1、 Working principle of equipment

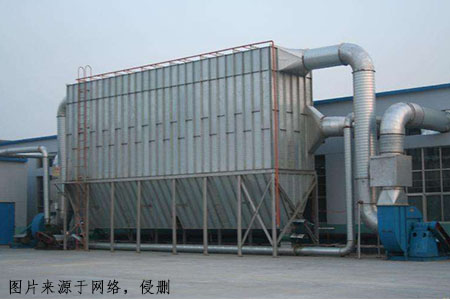

The dust collector is composed of upper box, ash hopper, ladder platform, support, pulse ash cleaning and ash discharging device. After the dust gas enters from the upper air inlet of the ash hopper, under the action of the wind deflector, the air flows upward and the flow rate decreases. Part of the large particle dust is separated and falls into the ash hopper due to the inertial force. The dust gas enters into the middle box body and is filtered and purified by the filter bag. The dust is blocked on the outer surface of the filter bag. The purified gas enters into the upper box body through the filter bag mouth and is discharged from the air outlet.

With the increasing dust on the surface of the filter bag, the pressure difference between the inlet and outlet of the dust collector also increases. When the resistance of the dust collector reaches the set value, the control system sends out the dust cleaning command, and the dust cleaning system starts to work. First of all, the solenoid valve is opened immediately after receiving the signal, so that the compressed air in the upper chamber of the small diaphragm is discharged. Due to the change of the force on both ends of the small diaphragm, the exhaust channel closed by the small diaphragm is opened, and the compressed air in the upper chamber of the large diaphragm is discharged from this channel. The force on both ends of the large diaphragm changes, so that the large diaphragm acts, The closed output port is opened, and the compressed air in the air bag is sprayed into the bag through the output pipe and the injection pipe to realize ash cleaning.

When the control signal stops, the solenoid valve closes, the small diaphragm and the large diaphragm reset one after another, and the injection stops. When there is a certain amount of ash in the ash bin, the level detector of the ash bin will send out the ash discharge signal, and the ash will be discharged through the ash discharge system of the dust collector.

2、 Transformation of ash discharge system

1. Transformation ideas. In the case of realizing the same function, the simpler the device is, the less likely it is to fail. After consulting the data and comparing the dust discharging methods of the same type of dust collector, it is decided to use the dust collector to discharge the dust and abandon the original dust discharging device.

Vacuum truck is a kind of special equipment which uses pneumatic conveying theory, air as the carrier, vacuum pump as the power source of dust, collects bulk or scattered materials and dust, and transports them to other designated places. It has the functions of long-distance transportation, collection and cleaning, which can not only solve the problem of dust emission, but also make full use of dust.

For the dust collector with auger device, when the ash bin is full, the auger will not rotate, resulting in the failure to discharge ash. Therefore, we need to change the ash area under the ash bin by changing the internal structure of the ash bin, so as to reduce the pressure of ash in the ash bin on the auger, reduce the rotation resistance of the auger, and make the auger rotate smoothly to discharge ash.

According to this idea, the contact area between the ash and the auger in the ash bin is adjusted by the internal partition of the plug valve to ensure the smooth discharge of ash in the ash bin. This kind of dust collector uses the straight pipe connected to the belt to discharge ash. For this kind of dust collector, we set up another pipe and use the dust collector to absorb ash to achieve the purpose of smooth discharge.

The other is a dust collector with two or more independent ash bins. The original design of this kind of dust collector is to adjust the amount of ash when discharging through the plug-in valve, use the star type ash discharge valve to adjust the discharging speed and play the role of sealing, and then discharge directly to the belt through the scraper machine. For this kind of dust collector, we can retain the original plug-in valve and star type ash discharge valve to adjust the discharging speed, And then set up the pipeline, through the dust truck to put ash, because the dust truck is using negative pressure dust suction, so there must be air inlet. Because there is a certain pressure on the left and right sides, the air flow enters along the right pipe orifice. When the dust in the dust collector falls down, it will be sucked away along with the air flow to complete the dust discharge process. The dust discharge in this way requires good sealing of all parts of the pipe, otherwise the negative pressure generated by the vacuum cleaner will be wasted due to air leakage. It can't discharge ash.

3、 Transformation effect and existing problems

1. Transformation effect.

After trial use, the reformed dust collector solves the design defects of the dust discharge system of the dust collector, and has obvious improvement compared with the indexes of the dust discharge system before the transformation

2. The ash discharging efficiency is greatly improved.

① The flexibility of ash discharging is greatly increased. Originally, it was always limited by the time and whether the belt conveyor was opened. After the transformation, as long as the dust collector shows that the ash bin needs to be discharged, the dust collector can be contacted at any time to discharge the ash.

② The recovery rate was improved. As the iron content in the dust is still considerable, we need to reuse the dust. Originally, the dust was discharged by scraper machine and unclosed pipeline, which caused dust in the process of transportation, and there was a certain amount of leakage. After being discharged to the strip, the dust could not be reused completely. After the transformation, the dust was directly driven into the disc ash bin by the dust collector, It can be said that the utilization rate can reach 100% if a certain proportion is directly mixed into the blending material.

③ The damage rate of cloth bag is greatly reduced. The designed service life of the original bag is 1-2 years, but the dust can not be discharged in time in the ash bin, which causes the dust to enter into the bag. Because the dust collector contains a large amount of iron element, the quality of the dust in the unit volume is quite large, which causes the bag to fall when the air is blow back. Through the transformation, the dust collector can discharge the dust in time, so that the dust will not accumulate in the bag and the service life of the bag will be greatly increased. In the future use process, improve the deficiencies, make the bag life gradually reach the design life.

④ The dust removal air volume increases. Due to the original can't discharge ash in time, resulting in bag blockage, making the dust removal air volume greatly reduced, after transformation, the dust removal air volume increased significantly, but due to the problem of design capacity, the dust removal effect is still not ideal.

2. There are still some problems in the dust collector. The transformation of the dust removal system of the dust collector does not involve the transformation of the air volume and the dust removal pipe network. Due to the insufficient design capacity, the air volume is obviously insufficient, and the pipe network layout is unreasonable, the air volume distribution at each point is unreasonable, and the structure resistance is relatively large, resulting in the dust removal effect is still not greatly improved. In the future direction of transformation, we will focus on the transformation of the pipe network and the expansion of the dust collector, so that the dust removal effect will be significantly improved.

4、 Summary

The transformation solves the practical problem that the dust can not be directly transported to the blast furnace, improves the flexibility of the dust collector, and the time of dust discharge is no longer limited. Moreover, the high damage rate of the bag is obviously improved, the air volume is obviously increased, and the dust removal effect is obviously improved.

(excerpt from the journal for reference only)